What is Dry Wall ?

Dry wall is a panel-based wall system made from lightweight aerated concrete sandwiched between fibre-cement sheets, installed using tongue-and-groove joints to form walls without brick or plaster work, enabling faster, stronger, and fire-resistant construction.

Manufacturing process :

1️⃣ Core Material Preparation

A lightweight aerated mix of cement and fly ash is prepared. This mix forms the structural core of the panel, giving it strength while keeping the overall weight low.

2️⃣ Sandwich Panel Formation

The prepared core is placed between two 5 mm fibre-cement sheets, creating a strong sandwich-type composite panel.

3️⃣ Edge Profiling

The panel edges are shaped into tongue-and-groove joints, which ensure easy alignment, faster installation, and precise finishing at site.

4️⃣ Curing & Finishing

The panels are cured and manufactured to accurate factory dimensions, then finished to enhance durability, strength, and surface quality.

5️⃣ Quality & Performance Testing

Each panel undergoes rigorous testing for mechanical strength, thermal resistance, sound insulation, and fire performance, as per ASTM, BIS, and BS standards to ensure safety and reliability.

Thickness Options:

- 50 MM — Lightweight Internal Partitions

Ideal for non-load-bearing walls, office cabins, and residential room partitions where speed, flexibility, and ease of installation are essential. - 75 MM — General Partitions & Walling

Suitable for most commercial and residential applications, offering a balanced combination of strength, sound insulation, and structural stability. - 100 MM — High-Strength & External Wall Applications

Recommended for heavy-duty partitions, high-traffic zones, and exterior wall systems, providing enhanced rigidity, durability, and impact resistance.

Installation process:

🔹 Step 1 — Fixing the Frame

The drywall installation process begins with setting up the metal framework. This framework acts as the structural support for the wall system. The channels and studs are carefully aligned and securely fixed to ensure stability, accuracy, and long-term strength of the partition.

🔹 Step 2 — Positioning & Screwing the Panels

Once the frame is ready, gypsum boards are positioned onto the metal structure. The panels are accurately placed and then fastened using self-drilling screws. This ensures the boards are firmly attached, flat, and properly aligned across the wall surface.

🔹 Step 3 — Filling Joints & Taping

After fixing the boards, the next step is joint treatment. A joint compound is applied along the gaps between panels, followed by reinforcing tape to strengthen the seams. This process helps create a uniform and crack-free surface across the wall.

🔹 Step 4 — Sanding for Smooth Finishing

The final stage involves sanding the treated joints and surface to remove any unevenness. This results in a smooth, seamless finish that is ready for painting, texturing, or further decorative treatment.

Design and Appearance:

-

Sandwich-panel construction with a sleek flat finish

The panel features an aerated lightweight concrete core enclosed between two uniform 5-mm fibre-cement facing sheets, providing a clean, even surface ideal for smooth wall finishes and coatings. -

Tongue-and-groove edge profile

The interlocking edges create tight, seamless joints, resulting in a neat, continuous wall surface with minimal visible gaps. -

Slim, space-saving profile

Available in 50 mm, 75 mm, and 100 mm thicknesses, these panels form thin partitions that increase usable carpet area while still delivering the appearance and performance of a solid wall. -

Lightweight panels with long, uniform dimensions

Promoted as the “longest, lightest, and strongest product for drywall construction,” the panels contribute to a modern, modular, and linear interior wall aesthetic. -

Suited for both internal and external walls

In interiors such as offices, malls, and residences, the slim partitions create a contemporary, streamlined look; in exterior applications, the insulated panels offer a solid-wall appearance with improved thermal performance. -

Prefabrication-friendly design

The uniform geometry and factory-made precision support clean-lined prefab structures, villas, camps, and site offices, enhancing a neat, modular architectural style.

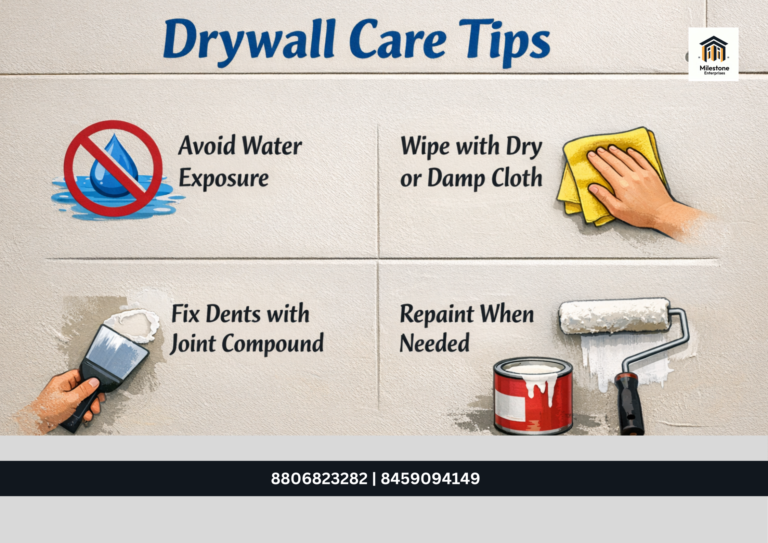

Maintenance:

Avoid Water Exposure:

Keep drywall away from leaks, moisture, and prolonged dampness to prevent swelling, stains, and structural damage.Clean with a Dry or Damp Cloth:

Use a soft dry or slightly damp cloth for routine cleaning instead of harsh chemicals or excessive water.Repair Dents with Joint Compound:

Fill small dents, holes, and surface imperfections using joint compound to restore a smooth, even finish.Repaint When Necessary:

Apply a fresh coat of paint when the surface looks worn or faded to improve appearance and add protection.