🏗️ What is Synthetic Thatch Roofing?

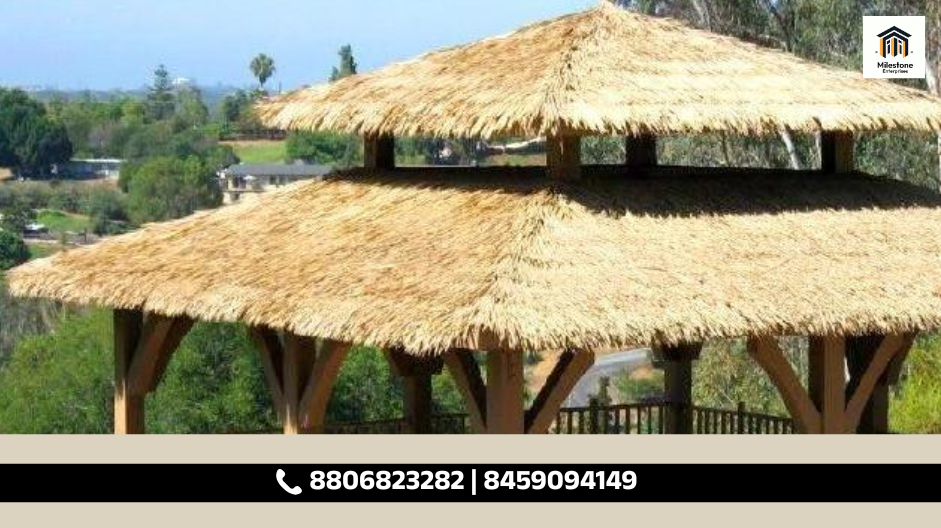

Synthetic thatch roofing (also known as artificial thatch) is a modern, long-lasting alternative to traditional natural thatch.

Instead of using dried grass or palm leaves, it is made from high-quality synthetic materials such as PVC, HDPE (High-Density Polyethylene), or PE resin that replicate the look and texture of natural thatch — but with superior performance, safety, and lifespan.

This roofing type is widely used in resorts, villas, eco-parks, theme structures, and outdoor pavilions, where designers want the aesthetic appeal of nature with modern durability and zero maintenance.

⚙️ Manufacturing / Making Process

- Material Selection

- Synthetic thatch is made using UV-stabilized, fire-retardant, and recyclable polymers (mainly HDPE or PVC).

- These materials are safe, weatherproof, and designed to mimic the color and texture of real palm leaves or straw.

- Molding & Extrusion

- The polymer material is heated and molded into leaf-like shapes or reed strands using precision molds.

- Some types are hand-shaped or heat-pressed to give a realistic natural effect.

- Coloring & Texturing

- Each piece is colored using UV-resistant pigments, so it does not fade under sun exposure.

- Multiple shades are blended to give a natural gradient look.

- Quality Testing

- Each batch is tested for fire safety, UV resistance, and flexibility before packaging.

🌿 Benefits

🌎 Sustainable Design: Made from recyclable polymers, supports green architecture.

🏡 Versatile Application: Suitable for resorts, cottages, villas, restaurants, and theme parks.

☀️ All-Weather Performance: Withstands rain, heat, snow, and wind.

🎨 Custom Styles: Available in various designs – African reed, Bali palm, Mexican palm, Fiji grass, etc.

🧩 Compatibility: Can be installed on existing natural thatch roofs for renovation.

🌤️ Advantages of Synthetic Thatch Roofing

✅ Zero Maintenance – No need for re-thatching, drying, or chemical treatment.

✅ Fire Resistant – Built-in fire-retardant materials enhance safety.

✅ Waterproof & Mold Resistant – Does not absorb moisture or rot.

✅ UV Protected – Does not fade or become brittle under sunlight.

✅ Lightweight – Easy to handle and install.

✅ Eco-Friendly – 100% recyclable and reusable.

✅ Aesthetic Appeal – Realistic tropical and rustic look.

✅ Pest Proof – Impervious to insects, birds, and rodents.

⏳ Lifespan & Durability

- Average Lifespan: 25–50 years (depending on material grade).

- No decay or color fading even under harsh UV exposure.

- Can withstand wind speeds up to 180 km/h (depending on structure).

🪪 Warranty

- Standard Manufacturer Warranty: 10 – 15 years (against fading, cracking, and corrosion).

- Fire-retardant certification: Available for premium grades.

- No annual maintenance warranty needed (unlike natural thatch).

🧹 Maintenance Requirements

- Practically maintenance-free.

- Occasional cleaning with water or air blower to remove dust or leaves.

- No need for re-coating, spraying, or pest control.

🧰 Installation Process

- Roof Framework

- A wooden, metal, or bamboo frame is prepared to support the synthetic thatch panels or strips.

- Can be installed on both new and existing roofs.

- Fixing the Thatch

- Synthetic thatch is supplied in panels, strips, or mats.

- These are fixed from bottom to top of the roof using screws, clips, or fasteners.

- Overlapping Layers

- Each layer overlaps the previous one (similar to natural thatch) to ensure complete water shedding.

- Ridge Installation

- The top ridge is covered with ridge caps or extra thatch panels for waterproofing.

- Final Touch

- Once installed, no coating or treatment is required — it’s ready for long-term use.

⏱️ Installation Time:

- 40–60% faster than natural thatch.

- Small gazebo: 1–2 days

- Large roof: 5–7 days